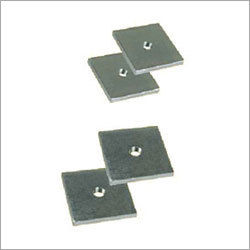

Striker Nuts

Striker Nuts Specification

- Accuracy

- High Precision

- Surface Treatment

- Zinc Plated

- Power Source

- Manual/Mechanical

- Accessories Type

- Fastener Accessory

- Operating Pressure

- Atmospheric

- Features

- Corrosion Resistant, Durable, Precise Threading, Easy Installation

- Machine Type

- Lock Assembly Machine Compatible

- Technology

- Mainstream Machining

- Type

- Striker Nut

- Material

- Mild Steel

- Function

- Provides a threaded anchor for fastening applications

- Application

- Automobile, Structural Fastening, Sheet Metal Joining, Automotive Locks

About Striker Nuts

Pertaining to the clients' requirements, we have been committed to manufacture and export quality assured Striker Nuts. Our offered nuts are suitable for bolt applications in various engineering industry. Clients can avail these nuts in different specifications like hook ends, straight ends, custom shaped ends and offset ends. Our team of efficient professionals assures to use premium quality raw materials in the manufacturing of these nuts. Striker Nuts are stringently examined before the final dispatch to rule out the possibility of any defect.

These nuts are reckoned for their:

-

Dimensional accuracy

-

Corrosion & abrasion resistance

-

Flawless finishing

Reliable Performance for Automotive and Structural Fastening

Striker Nuts are designed with advanced machining and a protective zinc plating, making them ideal for demanding environments like automotive lock assemblies and sheet metal joining tasks. Their robust material and precision engineering provide a solid threaded anchor, ensuring both security and longevity in fastening operations. This makes them an essential accessory for manufacturers focused on high-quality outcomes.

Engineered for Durability and Easy Installation

Constructed from mild steel, Striker Nuts combine long-lasting strength with ease of use. The corrosion-resistant zinc surface and accurate threading simplify installation, minimizing effort and maximizing performance. These features are particularly beneficial in settings that require frequent fastening adjustments or exposure to harsh conditions.

FAQs of Striker Nuts:

Q: How are Striker Nuts installed in automotive and structural assemblies?

A: Striker Nuts are designed for straightforward installation using manual or mechanical tools. Their precise threading allows for quick insertion and secure attachment to sheet metal and structural components, commonly within automobile locks and fastening assemblies.Q: What is the process for manufacturing Striker Nuts with zinc plating?

A: Striker Nuts are produced through mainstream machining of mild steel, followed by a specialized zinc plating process. This ensures accurate dimensions, enhanced corrosion resistance, and consistent performance in demanding environments.Q: When should Striker Nuts be used in fastening applications?

A: Striker Nuts are ideal for usage in places where a durable, high-precision threaded anchor is required, such as automobile lock assemblies, sheet metal joining, and other structural connections that demand reliability and corrosion resistance.Q: Where can Striker Nuts be applied within the automotive industry?

A: Striker Nuts are widely used in automotive locks, structural fastenings, and sheet metal joining tasks. Their compatibility with lock assembly machines makes them suitable for large-scale production and specialized automotive applications.Q: What are the benefits of using zinc-plated Striker Nuts over standard fasteners?

A: Zinc-plated Striker Nuts offer superior corrosion resistance, high precision threading, and enhanced durability compared to standard fasteners. These attributes contribute to longer service life and consistent performance in challenging atmospheres.Q: How does the precision engineering of Striker Nuts contribute to their reliability?

A: The high degree of accuracy in machining ensures that Striker Nuts provide a dependable threaded anchor, minimizing installation errors and delivering reliable fastening strength for both manual and mechanical processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Components Category

Industrial Spindles

Machine Type : Lathe, Milling, Grinding Machines

Application : Industrial Machinery, CNC Machines

Function : Precision Rotation/Workpiece Holding

Technology : CNC Machined

Features : Corrosion Resistant, High Rigidity, Long Service Life

Surface Treatment : Polished / Heat Treated

Copper Spuds

Machine Type : Electrical Fittings

Application : Switchgear, Transformers, Electrical Panels

Function : Provides Stud or Connection Point in Busbar Systems

Technology : Forged and Machined

Features : Corrosion Resistant, High Conductivity, Sturdy Construction

Surface Treatment : Electro Tinned Finish

PC Glass

Machine Type : Cutting, Bending, Thermoforming Machines Compatible

Application : Industrial, Construction, Automotive, Electronics, Safety Shields

Function : Transparent Protective Sheet

Technology : Injection Molding

Features : High Impact Resistance, UV Protection, Lightweight, Shatterproof

Surface Treatment : Smooth, Glossy

Send Inquiry

Send Inquiry